The Baixio de Irecê Project is a strategic government initiative, set to transform the semi-arid region of Bahia (northeast Brazil) through large-scale agricultural development. With the construction of dams and canals, and the installation of mechanized irrigation systems, the project aims to foster economic and social growth in an area historically marked by adverse environmental conditions and prolonged droughts.

Several thousand hectares of the project’s land are already under pivot irrigation, with plans to expand the irrigated area to 116,139 acres in due course. The main crops currently grown are cotton, soybeans, corn, beans, as well as fruits such as mangos and melons.

The family-owned company Agropecuaria Vilani is among those who have embraced the challenge of unlocking the area’s farming potential. The Vilani family have an extensive agricultural history, which started in Rio Grande do Sul. In the 1980s, the family relocated to Mato Grosso in Primavera do Leste, where they first implemented center pivot irrigation. Today, the Vilanis are irrigating an impressive 2,470 acres with center pivot technology – an area they are hoping to increase to 7,400 acres in the course of the project.

Irrigating in a semi-arid region like Baixio de Irecê presents significant challenges. The high temperatures and low humidity lead to an increased rate of evaporation, while frequent winds cause water losses and interfere with distribution uniformity. To address the low rainfall and high evapotranspiration, the installed pivots feature a large, 12-inch main pipeline, and operate with a flow rate of 4,843 GPM – delivering an 0.31-inch layer of water per day.

While this approach solves one issue, it also comes with challenges of its own. A particular problem has been wheel rutting of the center pivots, caused by the high flow rates and the heavy weight of the equipment. And, of course, with output volumes like these, only the most precise and efficient water management can ensure the sustainability (and profitability) of the system.

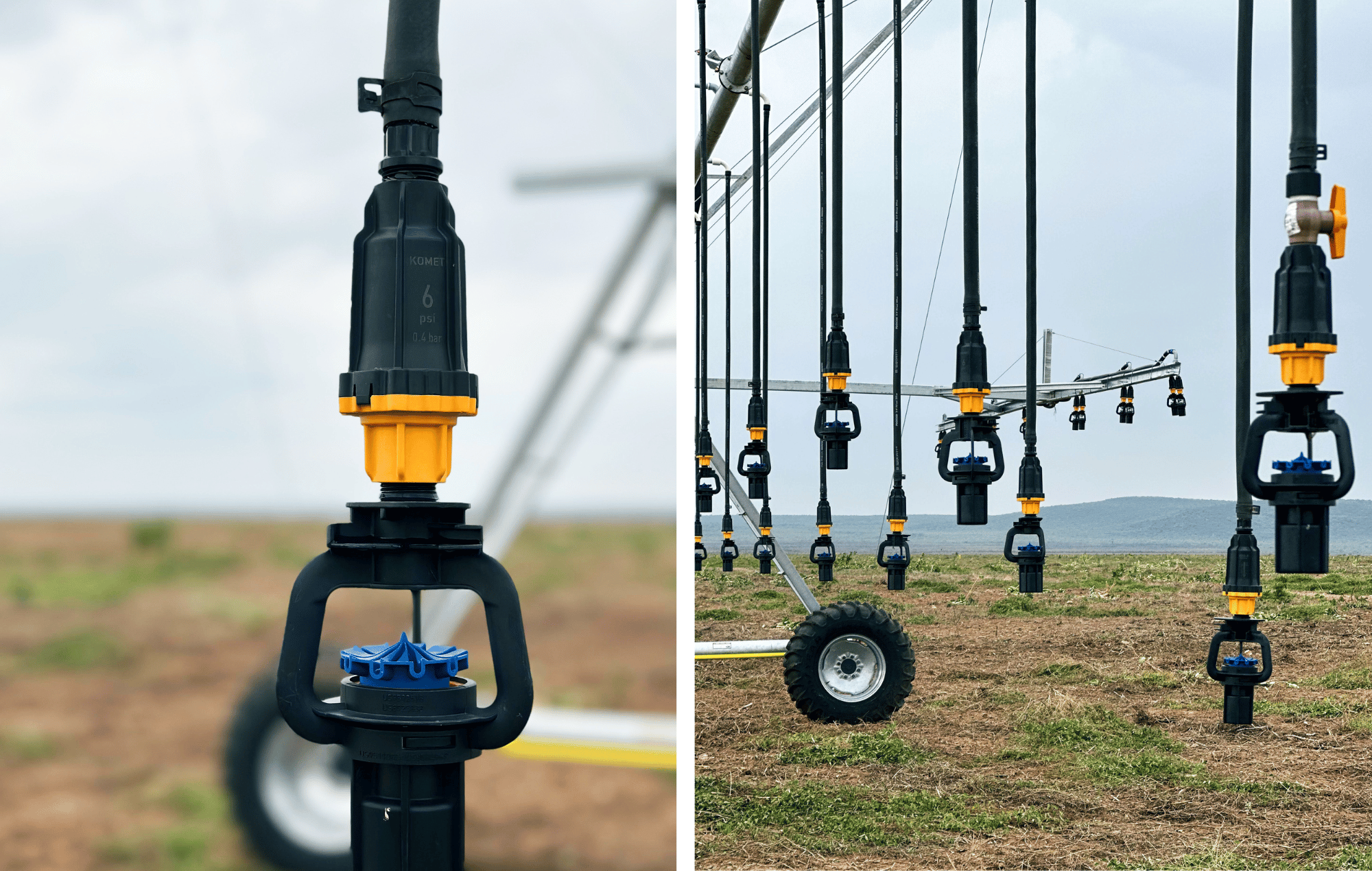

This is why Vagner Vilani contacted his regional Komet representative, Eugenio Lucca, and requested an on-site consultation. His aim: reducing losses, ensuring dry wheel tracks, and improving the overall performance of his pivots. To start with, Vagner was offered to test the Komet KPT with a low-angle (Blue Plate) deflector, paired with KPR-X 6 PSI pressure regulators. This solution was designed to combat wind drift and minimize evaporation losses by producing larger droplets with a consistent size across the whole irrigation pattern.

Vagner then conducted a series of field tests and performance analyses, with a core focus on efficiency and uniform distribution. Though he also tried out sprinklers by other brands, the KPT’s results were particularly impressive: irrigation efficiency increased from 72% to 94% compared to his previous sprinkler package – complemented by a noticeably improved crop performance.

The final challenge was to prevent the pivots from getting stuck in wet wheel tracks – a common problem with systems that have a high flow rate and a heavier structure due to their larger main pipe. To this end, Eugenio suggested the KPT PC (part-circle) sprinkler with a 180º irrigation pattern. Thanks to its advanced, high-precision design, the KPT PC not only keeps the wheel tracks dry and the pivot moving – it is also the only part-circle sprinkler on the market to deliver a consistent droplet size, proven to minimize losses through wind drift and evaporation.

Are you growing crops in challenging conditions? Our consciously streamlined product range is designed for ultimate versatility, durability and efficiency in all environments and terrains. Simply contact your nearest Komet expert for a personal consultation!